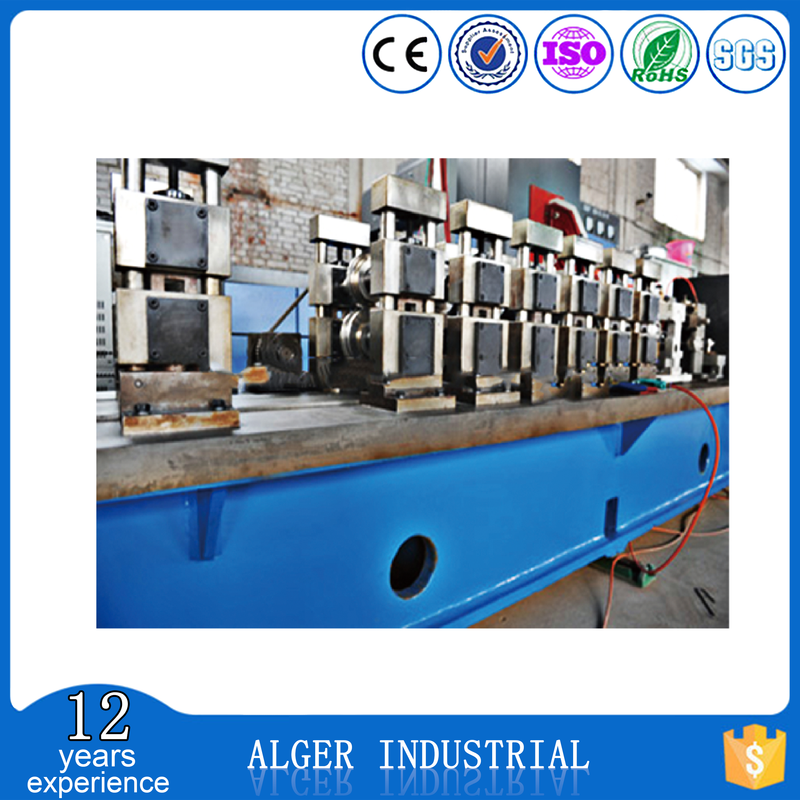

Warm edge spacer making machine

Warm edge spacer making machine

Warm edge spacer making machine

- Detail

- Parameters

Technical solutions

Basic principles of technical options

1.Advancement, the project adopts technology close to the international advanced level or domestic leading level.

2.Applicability, the adoption of technology should be compatible with the possible equipment, staff quality and management level and environmental protection requirements.

3.Reliability, the use of technology and equipment should be tested by production and operation, and have a good and reliable record.

4.Safety, the project uses technology, and it should ensure safe production operation in normal use.

5.Economic rationality, using advanced equipment, safe and reliable, should focus on whether the adoption of technology is economical and reasonable, whether it is conducive to saving investment and reducing costs, and improve comprehensive economic benefits.

Process technology flow

Process description

The warm edge rubber strip is an optimized fusion of the warm edge insulating glass edge sealing material and the door and window curtain wall sealing system, and is composed of a warm edge rubber strip, the special glue, the hollow special glue, and an EPDM rubber strip. Its unique composite laminate structure, 4-8 point edge structural seal, multi-point independent air isolation system design to ensure compliance with the European Union EN1279-2:2002 standard, to achieve a 50-year life of insulating glass.

Main process flow chart:

Equipment plan

Equipment selection principle

1.Determine the specifications and quantity of process equipment according to product production process requirements and process parameters.

2.Under the premise of satisfying the process production, the equipment with advanced and high performance is preferred.

Equipment selection analysis

The production equipment of the project is selected from joint venture equipment, and the equipment level has reached the international advanced level on the premise of meeting the production requirements.

The main production equipment

Engineering design

Mixer machine Kneader

Extruder Extruder

Pulling machine Cooling unit

Collecting coil Tape laying table

Simi-finished product

Infrastructure design

Water supply and drainage design

1.Water supply

Water use in the region includes industrial water, domestic water, fire water, green water, and unforeseen water consumption. Among them, the unforeseen amount

water is calculated as 10% of the sum of the above water consumption (excluding fire water consumption). The atmospheric water supply method is adopted, and the

water supply main pipes are laid along the main roads in the area of the economic production base, and all are connected into a ring.

Drain

Rain and sewage drainage systems are used. The washing wastewater and the fecal sewage in the domestic sewage are discharged separately, and the fecal sewage enters the septic tank primary treatment through the outdoor inspection well, and then discharged into the sewage pipeline, and is uniformly transported to the treatment plant for treatment and reuse. Industrial wastewater must be discharged into the urban pipe network after it has been initially treated. Sewage pipelines shall be arranged along all levels of roads, and sewage lift pumping stations shall be installed at places where the buried depth is too large. The sewage is transported to the sewage treatment plant, and after the unified treatment reaches the standard, the recycled water is used for car washing and pouring greening, roads, squares, etc., to improve the reuse rate of water.

2.Sewage system

The sewage in each block is treated separately in the previous stage and then collected in the urban sewage treatment system through the drainage pipeline and sent to the sewage treatment plant for centralized treatment. The water reuse system is used in areas where industrial plants are concentrated to reduce sewage discharge and save water.

3.Rainwater system

The rainwater drainage system of each building of the project should generally adopt organized drainage; the outdoor rainwater is collected by hard paving and rainwater outlets of roadside ditch, and is discharged into the field through the rainwater pipe.

Powered by

The power supply system is introduced in a double circuit underground 10KVA power supply line, and uses a ring network structure to open the ring. The 10KVA and below lines in the plant area are all buried in the ground, and the general control room is set up. According to the distribution of the power load, the box type transformers are set according to local conditions, and then distributed to the various power facilities. Lighting facilities in public spaces such as road plazas are uniformly arranged in the plant area

Main raw material supply

Each production line of warm-edged strips produces a total of 300,000 meters per year. The raw materials are selected by high-quality suppliers to ensure product quality

Standard

Service support

1.24 hours technical supporting by e-mails.

2.24 hours calling service & online service.

3.Oversea door-to-door service available.

4.User manual and detailed operating video/CD available.